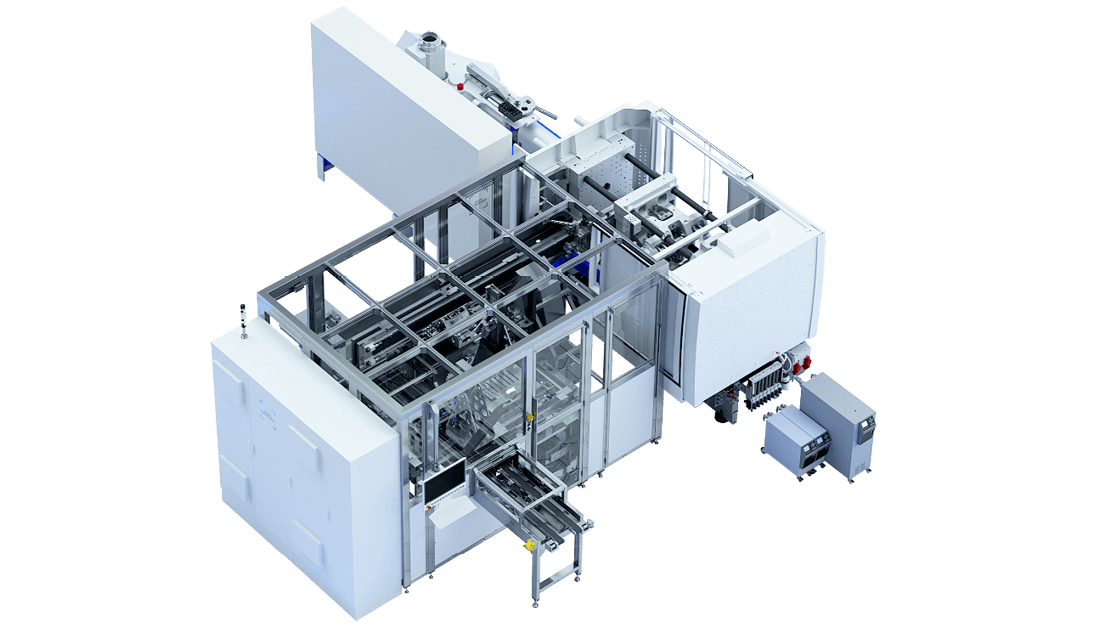

MA micro automation takes the alternative way as a special machine manufacturer and offers its customers the option of project realisation as general contractor in addition to the fully automated pipette tip & reaction tube end of arm tooling automation with MA X-Tip. MA micro automation relies on long-term strategic partnerships with well-established European injection moulding machine and tool makers. This enables an optimal coordination of the critical production parameters between the injection moulding process and the downstream production-proven automation.

By using 16 to 128 cavity moulds, various pipette tips can be produced on the injection moulding machines. The unloading is done by an innovative, linear driven handling system, which can be adapted to the given number of cavities with only a few changeover steps – universally scalable. The required grid dimension of the final rack is realised with a sophisticated handling strategy, so that the pipette tips are placed in the rack after a few automation steps.

The racks are transported, loaded and output fully automatically into the MA X-Tip via a buffer/conveyor line.

In addition, our customers have access to an MA X-Tip configurator that has no limits. MA micro automation offers its customers the flexibility to configure their desired solution. From various 100% optical inline inspections, pipette filter assembly, fully automated connection to upstream & downstream production processes (rack, aging storage, packaging, etc.) and the fully automated intralogistics process.

Technical data

- Fully automatic unloading of pipette tips from 32-cavity to 64-cavity moulds

- Linear handling system (unloading time of pipette tips including transfer < 1.0 seconds)

- Injection moulding cycle time 4.8 seconds (including removal)

- Pipette tip handling