Taking industrial manufacturing

MA micro automation develops and builds assembly, adjustment and testing systems for its clients in industrial manufacturing in the field of medical technology and visual inspection. Wherever possible, we rely on widely established standard modules and supplement them where necessary with specially developed individual components and modules.

Our competences

Dosing | Gluing | Curing

- Precise nano dosing with volumes

as low as 2 nl - Precise glue dispensing

(dot size of 150 μm diameter) - High Speed UV curing

- Controlled thermal curing

- Leakage / Pressure testing

Application examples

Cannula assembly

Fully automatic high-performance

assembly system for medical cannulas &

protective parts (3 variants) with a

cycle timeof upto 110 components/minute…

Precision Assembly

- Positioning accuracy ± 2 μm

- Ultra-precise positioning in

six degrees of freedom - Ultra-low step size: 0.01 μm

- High repeatability: 0.15 μm

Application examples

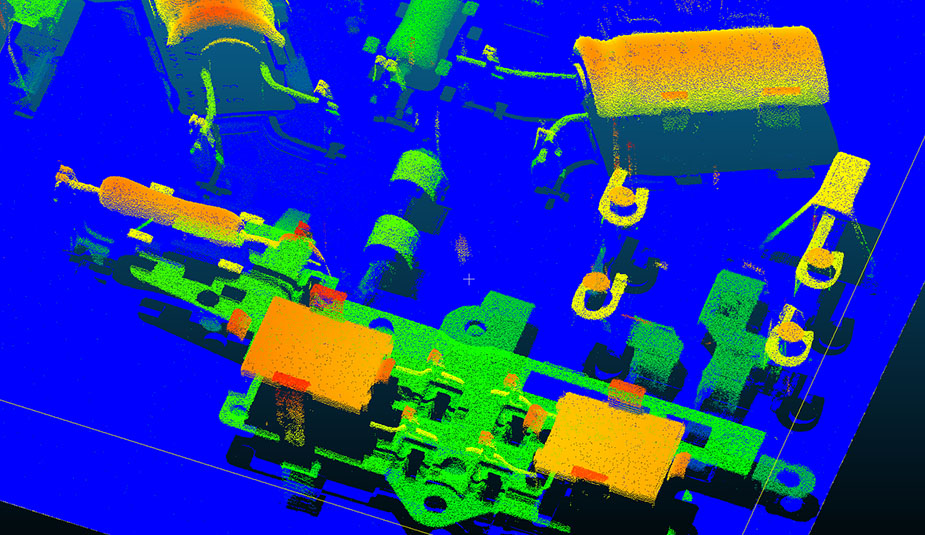

Optical 3D measuring system

Non-contact 3D data acquisition

– Light sectioning

– Calibrated measuring volume…

Special Handling & Separation

- High Speed Linear Handling System

(25kg load) - POC Strip Cutting & Handling

- Contact / Intra Ocular Lens handling

- Soft Silicone part handling

- Needle separation

(Canula, Lancets, Insulin Patches) - Stacking

- Siliconization

Application examples

Cannula assembly

Fully automatic high-performance

assembly system for medical cannulas &

protective parts (3 variants) with a

cycle timeof upto 110 components/minute…

Pen injector assembly

Precise, cleanroom compatible, fully or semi-automatic assembly of a pen injector from a different number of individual parts with a…

Slip-on shaft assembly

Fully automatic high-performance assembly line for slip-on shafts (toothbrush head) with a cycle time of 120 parts per minute…

Automated Optical Inspection

Measurement

- Precise 2D & 3D Dimensional measurement

Defects

- Moulding / Extrusion Defects

- Precise defect inspection up to 1 μm

- Foreign particle detection

- 21 CFR Part 11 Support

Application examples

Contact lens inspection

Customer-Specific Characteristics

Guarantee of stable processes in lens production, handling, gripper and dosing…

Disposables – Pipette tips, reaction tubes and cuvettes

Automation solution for in-vitro diagnostics

Millions of disposables – pipette tips, reaction tubes or cuvettes –

are needed and used every day for analytical…

Best In-Class Service

Pre-Engineering Consultancy

- Complete line integration

- GMP validation (DQ, IQ, OQ)

- Cleanroom Experience (up to ISO class 6)

Business Segments

This might also be of interest to you

Contact us

MA micro automation GmbH offers an extensive range of standardised and individual service contracts. Just send us a message via our contact form. We will be glad to help you.