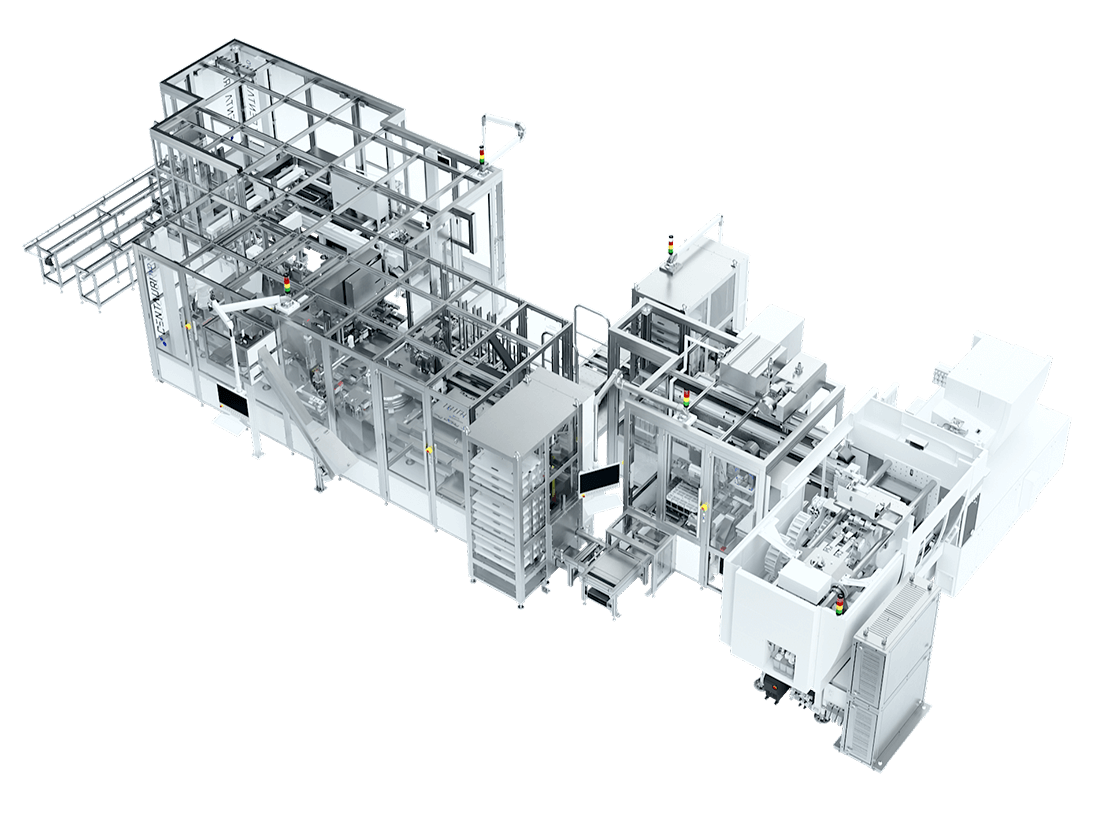

The demand for pipette tips has exploded due to the pandemic, while the requirement to manufacture them accurately and efficiently remains. As specialists in high-end automation, MA micro automation accepted the challenge to create a modular system supporting up to 64-cavity injection molding. What’s so special about our solution? A wide range of inspection tasks are integrated into the CENTAURI IVD, made possible by our extensive in-house image processing expertise. MA micro automation is the only supplier in Europe producing a high-speed linear handling system integrating linear motor and conveyor technology for parts removal and processing.

Pipette tips are both bulk and precision items used in laboratory diagnostics instruments to aspirate and dispense precise quantities of liquids. Part wall thickness and openings at the tip must vary by only a few tenths of a millimeter. So, any deviation of part geometry can potentially affect diagnostic results. That makes it critical to accurately monitor product features for burrs or deformations during the production process and to reliably remove any non-conforming parts.

To avoid downtime with 24/7 operations, MA micro automation integrates a buffer storage system that provides a known good part capacity of ten minutes between the injection molding machine and downstream processes. Intermittent delays, such as label or filter availability, will not affect injection molding production. NOK parts are replaced with OK parts from the storage queue. As a batch run is completed, the buffer storage will efficiently and automatically be emptied.

The CENTAURI IVD has a modular design and can be customized to accommodate the following process steps:

Process operation

- Tool removal and check for completeness

- Transfer and ejection of first shots after start-up

- 100% inline inspection of pipette tips for burrs or short shots (360° detection)

- Transfers and handling to maintain 10-minute buffer capacity

- Removal option for quality shot inspection

- Reject NOK parts

- Press-in and verification of filters

- 100% inline test offset depth

- 100% inline top view inspection of inner and outer diameters

- 100% inline testing of particles for filters / core breakage of the filters

- SPC Concentricity Test

- Automatic loading of racks

- 100% inline check for full rack

- Thermal Transfer Print lot number and expiry date

- Apply verified labels to racks

- 100% Verify position and content of labeled racks

- Blister packaging of finished product

- Check through blister lid to verify contents

- Heat seal blisters

- 100% check for sealing errors

- Stacking of the finished blisters

Technical Specifications

- Clean room class: ISO Class 7

- Cycle time: 0.095 seconds per pipette tip

- Refill rate up to approx. 25%

- Buffer capacity after injection molding machine approx. 10 min

- Scalability with regard to tip size

- Product-adaptable grippers